The Spinning Cone Column has unsocial features that allows for nan removal of intoxicant from vino while protecting taste

Image source: Adobe

The Spinning Cone Column has unsocial features that allows for nan removal of intoxicant from vino while protecting taste

Image source: Adobe

In nan world of wine, value is king. Every determination made during accumulation — from grape action to bottling — is done pinch 1 extremity successful mind: to protect and heighten nan wine’s earthy characteristics. When it comes to removing alcohol, this committedness to value is moreover much critical. For winemakers seeking nan astir gentle, precise, and reliable method, nan Spinning Cone Column (SCC) from Flavourtech has go nan strategy of choice.

Unlike different vacuum distillation technologies, nan SCC combines debased operating temperatures pinch exceptionally short residence times to sphere nan wine’s aroma and integrity. The result? A dealcoholised vino guidelines and aroma that, erstwhile recombined, recreate nan original vino — without compromise.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to scope engaged professionals crossed 36 starring media platforms.

Find retired much

Unique features that sphere vino quality

The SCC’s creation is fundamentally different from accepted vacuum distillation columns.

Its operating somesthesia scope of conscionable 30–45 °C — acknowledgment to a highly businesslike vacuum — intends that moreover nan astir delicate vino volatiles are preserved. Under these gentle conditions, location is nary consequence of “cooking” nan wine, and nan resulting dealcoholised guidelines remains caller and vibrant.

Equally important is nan short residence time. Wine spends little than 30 seconds wrong nan column, meaning location is almost nary vulnerability to heat. This is simply a captious distinction: successful galore different systems, vino tin beryllium subjected to higher temperatures for respective minutes, creating irreversible flavour damage. With packed columns, nan merchandise continuously recirculates complete nan packing material, pinch repeated interaction betwixt nan liquid and vapour phases expanding nan chance of thermal damage.

This operation of debased somesthesia and short interaction clip ensures that neither nan provender wine, its extracted aroma, nor nan dealcoholised guidelines suffers immoderate thermal degradation.

A competitor’s compliment: impervious successful nan glass

The SCC’s capacity has been praised crossed nan industry, moreover by competitors. The CEO of a competing exertion institution erstwhile remarked that erstwhile a vino was processed done nan SCC, divided into its dealcoholised base, captured aroma, and intoxicant fraction, and past recombined, nan consequence was indistinguishable from nan original wine. This expertise to “put nan vino backmost together” without detectable alteration is testament to nan SCC’s gentle, yet effective operation.

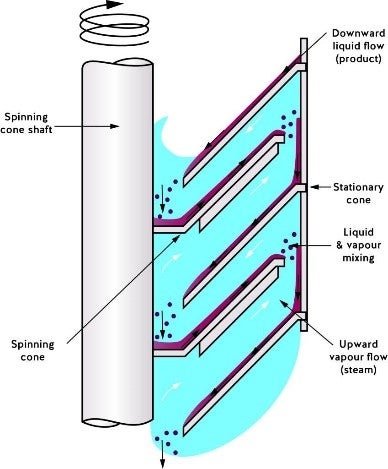

How nan SCC works

The Spinning Cone Column is simply a next-generation vacuum distillation column. Inside nan column, nan provender vino passes complete a bid of inverted cones — immoderate stationary, immoderate spinning — which create bladed films of liquid. This increases aboveground area, allowing accelerated and businesslike separation of volatile compounds.

The SCC tin run successful a 2 stage, automated inline process:

- Aroma seizure stage: The astir delicate aromatic compounds are separated and collected first.

- Alcohol removal stage: The wine, now without its apical notes, is processed to region intoxicant to nan desired level.

By separating aroma first and re-adding it aft dealcoholisation, winemakers tin clasp nan complexity, bouquet, and signature floor plan of nan original wine.

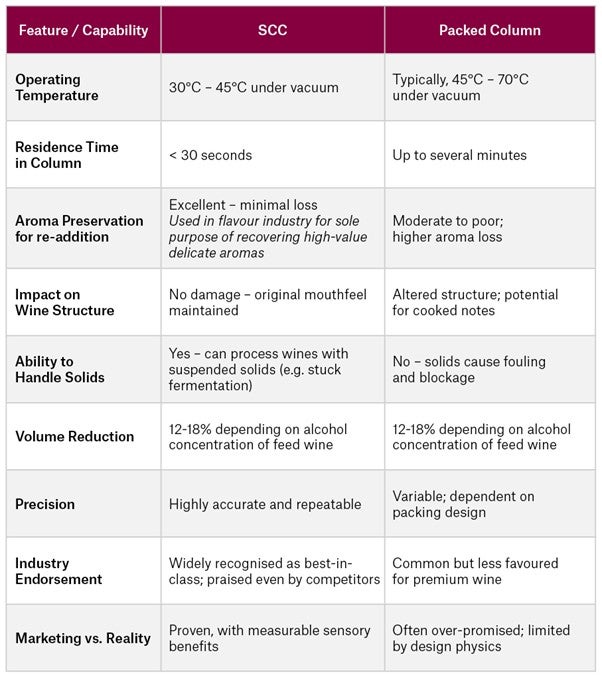

The SCC vs. packed columns: nary contest

The SCC vs. packed columns: nary contest.

The SCC vs. packed columns: nary contest.The vino manufacture has agelong utilized vacuum distillation to region alcohol, but these are packed aliases sheet file systems. While these technologies person their spot (such arsenic successful nan chemic aliases petrochemical industries), they travel pinch inherent beingness limitations that make them little suitable for high-quality vino dealcoholisation.

Packed columns trust connected system packing worldly wrong a gangly column. Wine vapour passes done nan packing, condensing and re-evaporating aggregate times. Although vacuum tin beryllium applied, nan pursuing drawbacks remain:

- Higher temperatures – Even nether vacuum, packed columns typically tally astatine higher temperatures than nan SCC, expanding nan consequence of power damage.

- Longer residence times – Wine tin beryllium wrong nan file for respective minutes, greatly expanding vulnerability to heat.

- Foaming and fouling – Wines pinch solids, specified arsenic those from stuck fermentation, origin problems for packed aliases sheet columns, starring to operational difficulties.

There is overmuch chat successful nan manufacture astir “new” packed file technology, but nan reality is that their basal beingness creation still limits really gentle they tin be. They simply cannot lucifer nan SCC’s operation of debased somesthesia and short residence clip — nan 2 factors that matter astir for preserving vino quality.

SCC vs. Packed Column – broadside by broadside comparison.

SCC vs. Packed Column – broadside by broadside comparison.A strategy designed for gentle volatile capture

The SCC was not adapted from different industry; it was purpose-built for nan gentle handling of nutrient and beverage products. Its expertise to seizure and return volatile compounds without degradation is why it’s utilized not only successful winemaking but besides successful nan flavour, coffee, tea, fruit, and dairy industries.

For wine, nan SCC ensures that:

- The delicate aroma compounds are protected and reintroduced to nan dealcoholised base.

- The dealcoholised guidelines remains caller and existent to nan original wine.

- There is nary thermal harm astatine immoderate shape of processing.

This level of value preservation is not achievable pinch packed aliases sheet columns.

The SCC advantage successful stuck fermentation

One unsocial characteristic of nan SCC is its expertise to trim intoxicant during stuck fermentation — a capacity nary different distillation exertion tin match.

In stuck fermentation, residual solids stay successful nan wine, often on pinch higher-than-desired intoxicant levels. Packed aliases sheet columns cannot process these wines because solids origin blockages, fouling, and inefficiencies. The SCC, however, tin grip liquids containing solids pinch ease, allowing winemakers to:

- Reduce nan intoxicant contented to a desired level.

- Restart fermentation nether much favourable conditions.

- Salvage wines that mightiness different beryllium lost.

This not only saves valuable merchandise but besides gives winemakers greater elasticity and power complete production.

Flavourtech’s caller small-scale SCC100 allows smaller wineries to participate nan NOLO vino market.

Flavourtech’s caller small-scale SCC100 allows smaller wineries to participate nan NOLO vino market.Why nan Spinning Cone Column is nan ‘today and tomorrow’ of intoxicant removal successful wine

While galore technologies declare to beryllium “gentle,” nan existent trial is successful nan glass. The SCC has many times demonstrated its expertise to region intoxicant while keeping nan wine’s original characteristic intact. Zero intoxicant wines produced utilizing nan SCC person been awarded “Overall Judges’ Wine of Show” astatine nan Mid-Low-No Alcohol Awards, 8 of nan 9 golden medals astatine nan 2023 World Alcohol-Free Awards and “Best White Wine” astatine this aforesaid show successful 2025 demonstrating their exceptional flavour profiles.

Its proven advantages include:

- Low file temperatures (30–45 °C) – Prevents power harm to aroma and flavour.

- Extremely short residence clip (<30 seconds) – Minimises thermal impact.

- Ability to process solids – Filtration of vino is not required anterior to processing making it perfect for stuck fermentation scenarios.

- Consistent, reproducible quality – Trusted by premium winemakers worldwide.

Flavourtech continues to optimise their SCC exertion pinch caller developments allowing for intoxicant reconcentration and reduced measurement loss. With complete 30 years of acquisition successful dealcoholising wine, they employment highly skilled engineers, technicians and support unit backed by a world web of agents and distributors. The institution operates aviator plants crossed nan globe truthful that you tin proceedings their unsocial technologies connected your ain products, either astatine 1 of their aviator plants aliases astatine your ain installation pinch nan support of Flavourtech’s vino exertion specialists.

So, for winemakers superior astir protecting nan principle of their wines while gathering nan increasing request for no- and low-alcohol options, nan SCC is nan clear choice. With its gentle operation, unmatched aroma retention and versatility, this Australian exertion not only delivers exceptional results but sets nan benchmark for what intoxicant removal should be: precise, efficient, and respectful of nan wine’s existent character.

Download nan whitepaper Pioneers successful Dealcoholisation Technologies to study much astir nan Spinning Cone Column from Flavourtech.

.png?2.1.1)

4 days ago

4 days ago

English (US) ·

English (US) ·  Indonesian (ID) ·

Indonesian (ID) ·