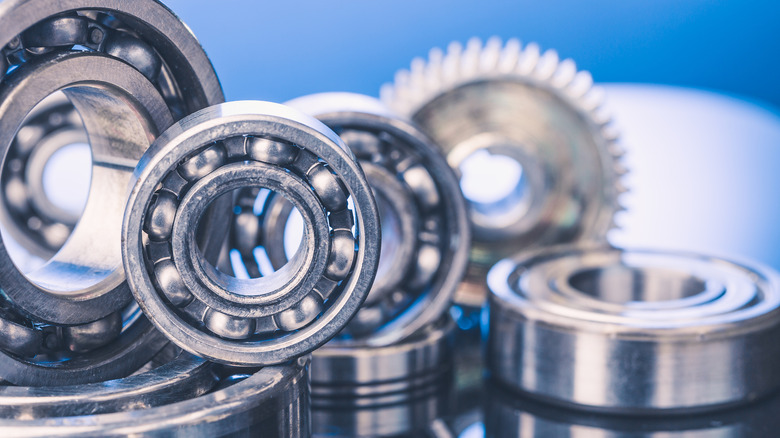

Nantonov/Getty Images

When automotive enthusiasts deliberation of ceramic, nan first point that comes to mind is the ceramic coating connected a car's paintwork. But it has different uses arsenic well, including successful nan manufacture of bearings. All shot bearings, ceramic aliases steel, person nan aforesaid basal job, which is helping loads rotate smoothly by reducing nan clash betwixt moving components. Where they disagree is successful nan materials they are made from and nan behaviour of that worldly successful different conditions.

Despite what they are called, ceramic bearings are usually not wholly made of ceramic. Purely ceramic bearings do exist, though, but because ceramic is acold much brittle than steel, they are mostly utilized successful low-impact applications.

Hybrid designs are much common, which person ceramic balls but their soul and outer races are made of steel. But moreover they aren't nan manufacture standard. That privilege goes to purely alloy bearings, which person alloy balls successful alloy races. They are tough, elastic, costs less, and are much tolerant of immoderate deviations successful alignment. Ceramic balls are usually made from silicon nitride aliases akin materials. They're highly hard, very smooth, non-magnetic, non-conductive, and resistant to corrosion. When heated, they besides grow a batch little than steel.

Myths of clash and velocity successful bearings

Netpix/Getty Images

The rolling guidance astatine nan interaction points of ceramic bearings is little because of nan smoothness of nan surface. This smoothness is owed to nan highly tight tolerances utilized successful their manufacturing, and nan polishing that's done for weeks after. It creates a pristine aboveground decorativeness and exceptional roundness. It besides forms nan ground of nan promises ceramic bearings are sold on: reduced clash and much speed.

However, conscionable changing nan worldly of nan shot doesn't magically driblet clash by a immense margin. There are different factors astatine play erstwhile it comes to generating resistance. Lubrication and seals are what nutrient nan lion's stock of clash wrong a bearing, whereas nan balls lend only a mini amount. Without addressing these factors, gains will stay limited.

In laboratory testing, ceramic bearings tin show little powerfulness loss, particularly erstwhile paired pinch ray seals and bladed lubricants. But erstwhile grease viscosity and seal contact, contamination, and real-world loads are introduced, those gains shrink dramatically. Independent testing has shown that high-quality alloy bearings tin lucifer aliases outperform ceramic bearings erstwhile lubrication and sealing are equalized. The accent is connected "high quality". Bearings are among those parts you should ne'er inexpensive retired on.

Durability, maintenance, and choosing what really fits

Palitsyn Evgenii/Shutterstock

Durability is wherever expectations and reality often diverge. Ceramic is harder than alloy and doesn't corrode, which sounds for illustration a look for agelong life, but hardness isn't nan aforesaid arsenic toughness. Ceramic is much brittle and little tolerant of shock. In hybrid bearings, nan hardness mismatch betwixt ceramic balls and alloy races tin accelerate title deterioration nether load aliases impact. Once that happens, clash increases and ratio drops.

Steel bearings, by contrast, use from matched worldly hardness crossed balls and races. They tolerate misalignment and imperfect installation acold better. This is why alloy bearings predominate heavy-duty and high-load applications.

Ceramic bearings often trust connected lighter seals and thinner grease to present their ratio advantage. That makes them much susceptible to contamination and increases attraction demands, truthful due greasing practices are basal for agelong life.

.png?2.1.1)

20 hours ago

20 hours ago

English (US) ·

English (US) ·  Indonesian (ID) ·

Indonesian (ID) ·